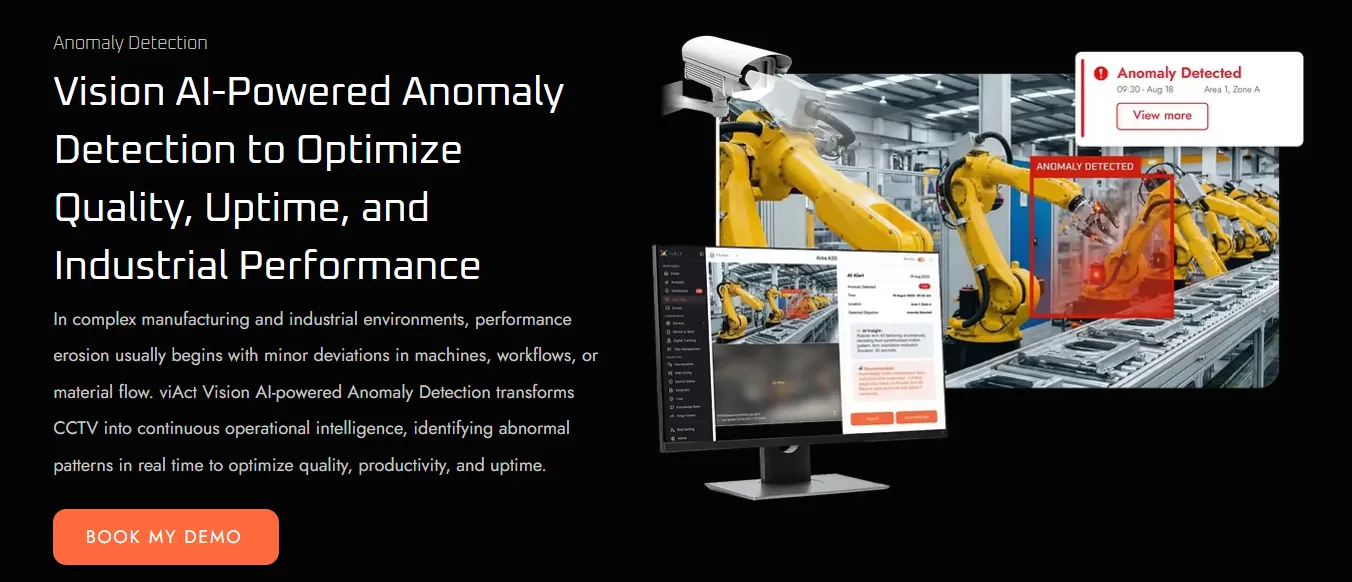

The Vision AI–Powered Anomaly Detection module by viAct is designed for complex manufacturing and industrial environments, enabling early identification of subtle deviations across machines, workflows, and material movement—often before they escalate into safety risks, quality losses, or production delays.

Key applications include:

• Detecting irregular machine movements or cycle-time variations

• Identifying unusual worker–machine interaction patterns

• Flagging abnormal material build-up or blockages

• Highlighting machinery downtime during planned production periods

• Spotting deviations in assembly sequences

• Monitoring congestion or misrouting within internal logistics

By applying AI-driven video analytics through existing CCTVs on site, this module introduces continuous situational awareness to the factory floor—transforming raw visual data into real-time, actionable operational intelligence.

No comments yet. Be the first to comment!